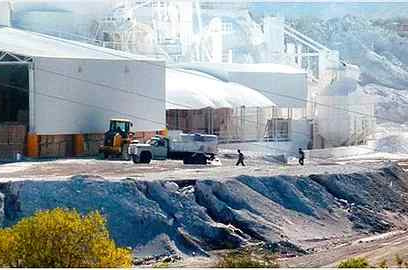

Its main town is Media Agua, the main urban center, and another important center is Los Berros. Its territory has a mountainous landscape to the west, with the presence of major mining operations dedicated to the extraction and processing of non-metallic minerals for the production of lime, mainly.

Characteristics:

High purity raw material: It has its own quarries in a region privileged by the quality of its limestone, which ensures a uniform and excellent quality raw material.

Stock for dispatch: The technology applied in production processes and the high production capacity which, combined with the amplitude of closed warehouses, allows us to have permanent stock in the entire product line. Supported by an important fleet of forklifts that enables customer satisfaction in time and form.

Quality control: own laboratories for quality control, where raw material and products are permanently controlled.

Production process:

The lime production process from the selection of the required raw material, Limestone, calcium carbonate (CaCO3) of high purity, which comes from the exploitation of our own deposits located only 5,000 m from our Industrial Plant. Detailed geological studies carried out on the same allowed us to determine:

-Corrected Measured Reserves: 5,500,000 Tons.

-Weighted Average Grade: 98.5 % Calcium Carbonate.

Crushing:

The material obtained from the exploitation of our deposits is subjected to a Primary Crushing process by means of jaw crusher, to then proceed to its Granulometric Classification in vibrating screen, in order to achieve size uniformity and a "closed" granulometric curve in response to qualitative requirements of its subsequent calcination process.

Liming:

The Limestone is transformed into Quicklime in Vertical Kilns of modern technology, using in the calcination process the "Mixed Bed" system, through the use of Residual Petroleum Coal as fuel. The excellence in the operation, on the part of the highly experienced and qualified personnel of the company, achieve through the control of the forced ventilation to which the unit is subjected, an absolute control of the different occurrences during the stages or zones of preheating, calcination, termination and cooling, in which the processes are classified and of extreme importance in the correct calcination with the technology used. Quicklime obtained from our kilns, of a quality such that it satisfies the most demanding markets, is marketed as Bulk Quicklime, in different granulometries, and as Ground Quicklime in different types or qualities, responding to its use as road, construction or industrial.

Hydration:

The Hydrated Lime resulting from the chemical process as a finely divided and extremely white powder, is subjected to granulometric classification in mechanical air separator, which allows a controlled adjustment of the required granulometry, obtaining basically four (4) products, which respond to different chemical qualities, depending on its Origin Quicklime, and depending on the Granulometric Classification obtained in the separator.

-SPECIAL HYDRATED LIME

-HYDRATED LIME

-CONSTRUCAL HYDRATED LIME (Formulated Construction Lime)

-MAGICAL HYDRATED LIME

Once the quicklime is obtained, part of its production is derived to the manufacture of hydrated lime or calcium hydroxide, a process that requires a previous milling of the quicklime for its subsequent pre-hydration:

1st Stage of "lime slaking" through the injection of precise quantities of water, responding to dosage according to chemical balance of reaction and under specific thermal conditions, attending to the exothermic of the mentioned reaction.

2nd Stage consists of the treatment of the resulting material in the Hydrator By Rebalance, where the reaction and formation of the resulting chemical compound Ca (OH)2, (Calcium Hydroxide) is concluded.

Quality control:

The different stages, described in the Process, are monitored by skilled and trained personnel from our Quality Control Department. Through random and systematic samplings and the availability of our own laboratory, for the required Chemical and Physical Analyses, it normalizes, according to specific procedures, a permanent follow-up and control of all the products involved in the different stages of the process, aimed at ensuring the full satisfaction of our customers.

Dispatches:

The advanced technology used in the production processes generate an important production capacity, which must be combined with ample closed warehouses that allow us to have an important stock, permanently for the entire product line, which supported by an important structure of forklifts / auto elevators, which together with the fleet of own cargo transportation and/or contracted trucks, enables customer satisfaction, according to requirements in a timely manner.

Limekiln:

The property of La Calera has 150 hectares.

It is located in the Department of Sarmiento, Province of San Juan.

Total surface: 169 hectares.

Composed of a 150 hectares lime kiln and a 19 hectares quarry.

Resources: 11.000.000 - 4.200.000 m3

Type of property: Concession - Quarry

Commodities: Limestone

Purity: Limestone at 98%.

Quarry:

Own water drilling with registration and authorization from the Hydraulic

Directorate of the Province of San Juan.

Industrial gas and electric power at door.

Green lung of 4 hectares of forestation.

Housing of 100 m2 and shed of 400 m2.

Plant I

It includes three vertical kilns of calcination by mixed bed of 13 m high and 2.8 m in diameter.

Its daily production capacity is 25 tons per day. Under a 1500 m2 enclosed shed containing: A quicklime crushing and classification plant.

A quicklime grinding plant

Two hydration lines with their corresponding classification, material storage silos and semi-automatic bagging system.

Plant II

It includes:

Six vertical mixed bed calcining kilns 15 m high by 3 m in diameter and a production capacity of 35 tons per day.

Two quicklime classification and crushing plants.

A 20 m x 20 m shed for refractory storage, with a 400 m2 under shed.

Maintenance workshop with a 300 m2 shed.

Office space, Scale

Two 100 m2 apartments for foremen, each of 100 m2.

Six houses for personnel of 50 m2 each.

Industrial gas and electric power at the door.

Waiting area for trucks for loading of 5 hectares with housing and forestation.